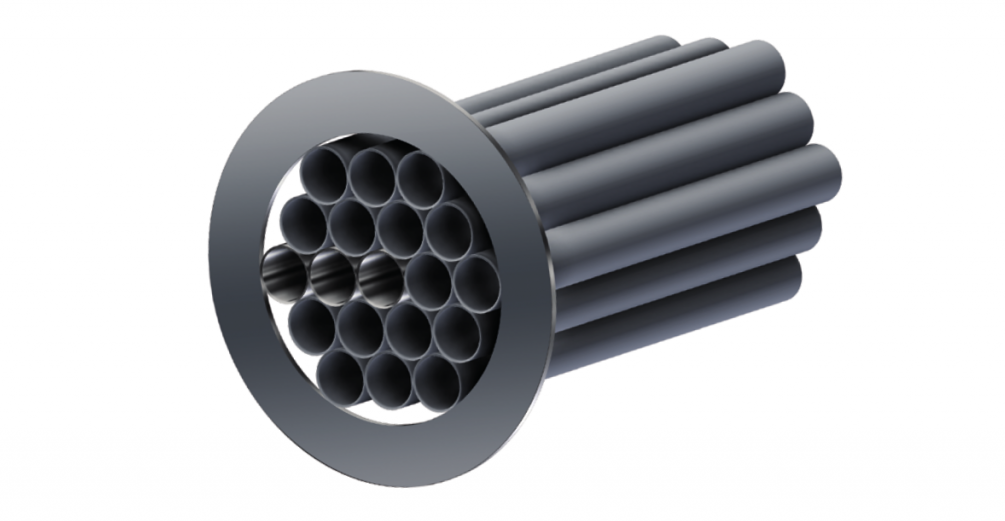

Flow conditioners are used to reduce the turbulence caused by a liquid flowing through piping. They are commonly used in domestic and commercial plumbing systems, as well as in industrial applications. This explains why an air flow conditioner is made from a variety of materials, including plastic and metal. They can be fitted onto existing pipes or installed inside new piping to improve the flow of liquids and gases through it. All, these is to ensure the conditioner fits different pipes appropriately.

Types of Flow Conditioners

There are several different types of flow conditioners available:

- Static flow restrictors: These devices have no moving parts; they are simply designed to restrict fluid flow at a certain point in the system. Static restrictors can be used to control pressure drop across a device or pipe section, or they can be used to limit maximum velocity through a section of pipe.

- Active flow restrictors: Active flow restrictors are similar to static units except that they contain moving parts within them that change their shape when fluid flows through them (usually by expanding). This allows active units to alter their restriction characteristics based on fluid conditions such as temperature changes.

What to Look for in Flow Conditioners

Flow conditioners are often used in conjunction with other types of filtration systems, such as sand or cartridge filters. They help to reduce the amount of debris that passes through your system. This can help to improve the performance of your filter and keep it from getting clogged up too quickly.

- Material Used: Look for a product made from PVC or CPVC plastic, which is non-corrosive and safe for use in drinking water systems.

- Size: Flow conditioners come in various sizes to fit different pipe diameters and flows. Make sure that you get one that fits your pipes perfectly so that it can be installed easily without causing leaks or other problems down the line!

- Type of Inlet: Flow conditioners come in two types: 2-way or 3-way designs. The former has an inlet at both ends while the latter has an outlet on one end only.So, choose whichever type fits your needs better!

Common Problems with Flow Conditioners

The most common problems with flow conditioners are:

Leaking. A leaking flow conditioner is a sign that the system is not working correctly. The most common reason for leakage is a hole in the filter. This can be fixed by replacing the filter.

Clogging. If your flow conditioner clogs up, it will restrict or prevent water from flowing through it at all. Clogging is most often caused by sediment building up in the filter and blocking it up. You can fix this problem by cleaning and replacing your filters regularly (at least once every six months).

Noisy operation. A noisy flow conditioner indicates that there may be something wrong with your system – check if everything’s running smoothly by testing your faucets and sinks to see if they’re functioning correctly.

Conclusion

The main purpose of Flow Conditioner is to condition liquids when passing through the pipe systems in the cooling tower before making contact with the air and corrugated tubes.

Flow conditioners prevent large objects from passing downstream through water pipes. This may sound like a simple application, but there are several features that make flow control devices worth researching into further.

So, if you are planning to invest in flow conditioners then capital cost should definitely be the first consideration that you ought to make. In fact, costs would always be responsible for the higher prices of the products made by leading manufactures. This means that it is possible to get benefit from cheap flow conditioners if only you learn how to recognize and appreciate the big difference between quality, durability and affordability.